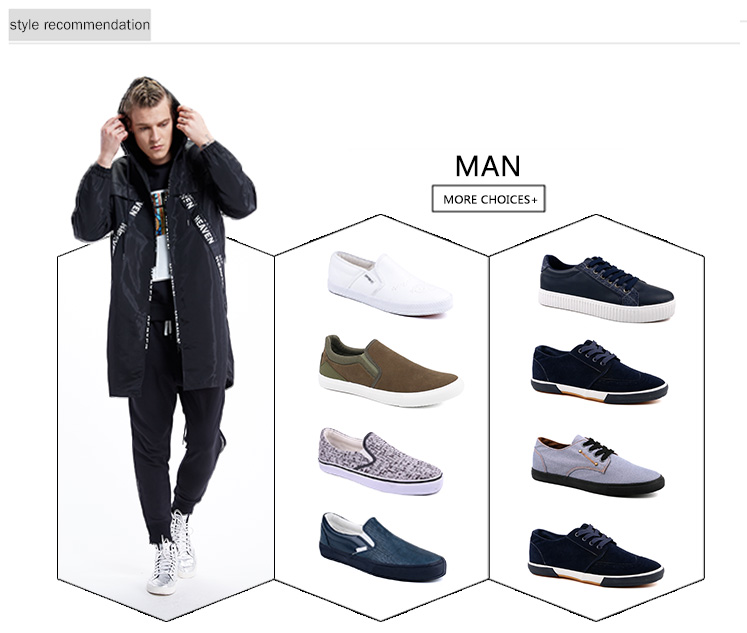

Related Products

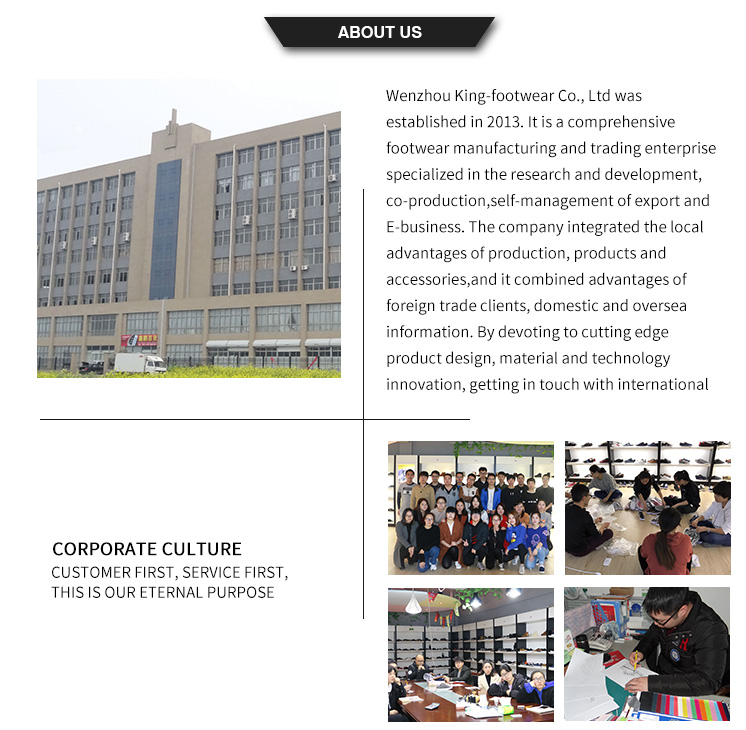

Copyright © 2025 Wenzhou king-footwear co., ltd | All Rights Reserved

Hello, please leave your name and email here before chat online so that we won't miss your message and contact you smoothly.